Your Custom Text Here

Over the past six years I have taken two classes and audited a third by Dale Brotherton owner of Takumi Company in Seattle Wa.

Over the past six years I have taken two classes and audited a third by Dale Brotherton owner of Takumi Company in Seattle Wa.

Workshop #2 - Entry Gate, Ashland OR.

Facilitated by Econest owner Robert Laporte the second class with Dale was a team build of an entry gate onto the property. Here Robert and I prepare a sub-post that attaches to one of the main gate posts.

Double Top Beam

The double top beam sandwiches the purlin supports.

A Great Project

Dales classes start with three days of tool set up and sharpening, the following three or four days we got it to this point and we were all very proud.

Audited Class - Chinese Gate, Snohomish

A very big Chinese designed gate, this time cut out of recently felled western red Cedar trees mostly from the property. And the weather was very wet, notice the tarp overhead. Dale answering my questions.

Keyed Locking Scarf Joint

Dale did the lay out and I did the cut out.

Success

For a first time and that the material had some checking in the area it turned out quite well.

Ridge Beam

The scarf joint was needed to add length to the ridge beam, which when finished was faceted into an octagon.

Too Big A Project

After more then a week of work this is how the project looked when I had to return home to my own project. It was decided that bigger equipment would be the safest route to assemble the rest of the parts we had prepared during the class.

Bainbridge Island - Bight

Hired on with Dale to help assemble and install some large structural Alaskan Yellow Cedar trusses that he and his aprentice cutout and finished.

Center Of The Room

These are the lower support sections of the trusses in the middle of the room assembled and ready for a lift.

Standing Tall

Putting the pieces together up in the air.

Portland Japanese Garden - Port Orford Cedar

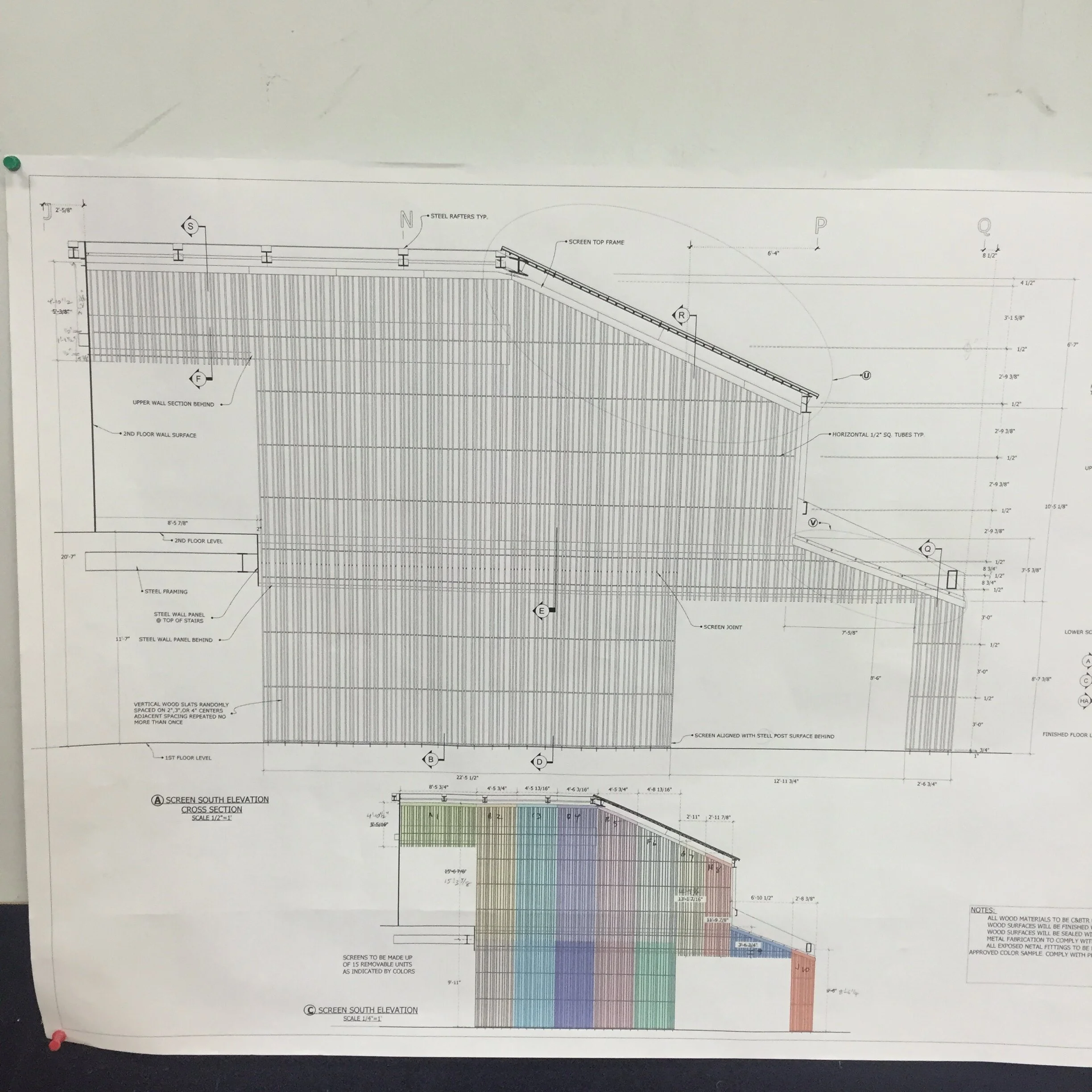

Another job with Dale, this time architectural elements in two of the new buildings at the garden. I got in on some finish planing for the “curtain” wall alongside the stairs in the learning center.

The "Curtain"

The assembly had an upper and lower section of groups approximately four foot wide. Here they are ready to be planed.

Not A Bad Shaving

How Many Boards?

I forget, but I did create a few nice piles of shavings.

Tuning It On Site

This particular section was fit to its top beam on site before installation.

The Cafetria Ceiling

A detail of how the ceiling boards were fastened to allow movement.

Pyramid Ceiling

Three of the four faces of the ceiling are wood panels attached by fixed keyed brackets to a frame suspended from the metal above. The miter joints between the boards from the bottom up to the apex look as tight as the day we installed them.